coaxworks - Now on Europages

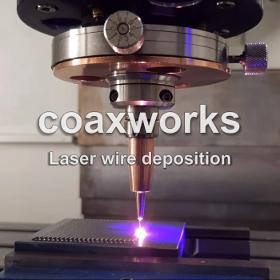

coaxworks - Now on Europages ・ 22. Jan. 2021About coaxworks GmbH The company coaxworks is your expert for systems technology and services for direction-independent, wire-based laser metal deposition and laser cladding. We provide both, standard and customized coaxial multi-beam laser heads with centric wire supply. As a retrofit for your laser cell, as an upgrade for your welding robot or as mounting kit for your serial machines – there are numerous options. You are also looking for solutions for wire feeding, process monitoring or inert gas atmosphere for high-quality operations? As a Fraunhofer IWS spin-off we keep up with the latest developments in handling a multitude of wire materials. To keep you going, we offer feasibility studies, installation service and training with our products. Let’s bring your production to the next level. coaxworks - UPGRADE YOUR WELDING