- europages

- >

- Thermische Bearbeitung von Stahl und Metallen

- >

- COAXWORKS GMBH

- >

- Laser wire deposition

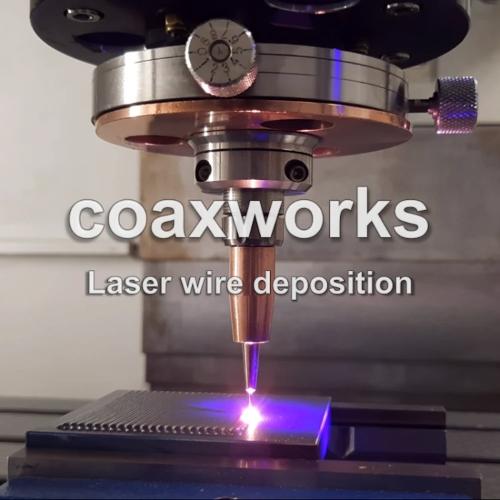

Laser wire deposition

coaxworks - Innovations for Laser Wire Deposition

Beschreibung

By using our coaxial laser welding head wireM, the welding process can be carried out independently of the direction, so that the coatings can be applied not only to rotationally symmetrical but also to flat and freely formed component surfaces. By selecting the wire filler material according to the requirements, the achievable coating properties can be adapted to the desired requirements. Characteristic features: > A low energy input causes a flat penetration by mixing the welding wire only minimally with the component material. > Complete utilisation of the filler wire results in particularly clean process conditions for human and machine. > By selecting the laser power and the wire diameter, the layer thickness can be varied and thus only as much material as necessary can be applied in a cost-efficient manner. > The use of the SGC500 shielding gas chamber for welding in an inert, oxygen-free process atmosphere makes it possible, for example titanium and iron materials.

- Thermische Bearbeitung von Stahl und Metallen

- Cladding

- Beschichtung

- Auftragschweißen

Videos

Ähnliche Produkte von COAXWORKS GMBH

COAXWORKS GMBH

Deutschland

With the SGC500 portable shielding gas chamber, coaxworks offers a separate machinery component for CNC and robot-based laser wire welding processes. By means of a flexible foil tent and an additional adapter on the laser welding head, a high-purity shielding gas atmosphere can be set up. Bottom connections for a continuous flow of inert argon gas allow a stable oxygen content of less than 20 ppm after only 20 minutes. The SGC500 protective gas chamber has the following integrated technical features: > a handling flap on the front side for quick chamber loading when the foil tent is installed, > two glove ports at the front for component handling when the chamber is flooded, > a removable T-slot plate for defined clamping of components, > three viewing windows for process observation from the outside and > a quick-clamping system on the top for defined fastening of the foil tent. Special designs can be customised. Send us your specific request by e-mail!

Angebot anfordern

COAXWORKS GMBH

Deutschland

The coaxworks wireM laser welding head opens up new possibilities for surface repair and geometry modification of tools in metalworking. Areas of application are, for example, tools for sheet metal and solid forming, wear parts of construction machines or other functional components subject to abrasive stress. With the installation in a CNC machine or a robot laser system, the fully mechanical processing of simple surfaces up to complex three-dimensional tool surfaces is possible. We would be happy to advise you on how the full potential of surface repair can also be used for your workpieces. Send us an e-mail!

Angebot anfordern

COAXWORKS GMBH

Deutschland

The coaxial laser welding head wireM is an interchangeable equipment for robot and CNC laser processing machines. It convinces in research and teaching as well as in the industrial environment with a compact design, simple operability and durable robustness. The latest version offers numerous configuration variants and even more technical interfaces for peripherals. ☑ Flexible and direction-independent welding with robust 3‑beam design ☑ Productive processes with up to a maximum of 4 kW laser power and up to 2.5 kg/h deposition rate ☑ Minimal material influence on the workpiece due to precise laser beam ☑ Clean, resource-saving and low-maintenance installation solution through 100% utilisation of the filler wire ☑ Reproducible and long-term constant manufacturing quality due to automated mode of operation ☑ Collision protection integrated close to the process to avoid machine damage Send us your specific request by e-mail! coaxworks - Innovations for Laser Wire Deposition

Angebot anfordern

COAXWORKS GMBH

Deutschland

The coaxial laser welding head wireXL is expected to expand our product portfolio to a more powerful version from 2023: >> usable with laser powers up to 10 kW, >> built-in sensors for process-related monitoring, > a deflection sensor to protect against damage in the event of collisions or process errors, > an XYZ adjustment unit for precise adjustment of the laser spot – wire input arrangement, > shielding the built-in cover glasses by means of crossjet against splashes, > the reduction of fume contamination on the cover glasses by an integrated downjet and > the possibility to replace the protective glasses by means of interchangeable slides. Special designs are still possible on customer request. Send us your specific request by e-mail!

Angebot anfordern