- europages

- >

- Magnete

- >

- HME - TECHNOLOGIES GMBH

- >

- produkte

HME - TECHNOLOGIES GMBH

Schweiz

Hersteller/ Fabrikant

HME - TECHNOLOGIES GMBH

Schweiz

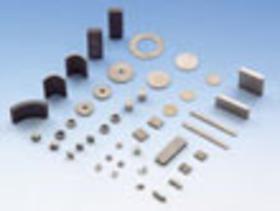

Very sensitive to counter field but highly resistant against corrosion, for high temperature application with low temperature coefficient. General Information: Alnico magnets are produced by casting process or by pressing and sintering process. The magnets are sensitive to counter field and highly resisitant against corrosion. They can keep their magnetism up to 550°C and have a very low temperatur coefficient. The material is composed of iron, cobalt, nickel, aluminium, copper, and niobium. Sintered alnico magnets can be made in more complex shapes than cast alnico which must be machined mainly by grinding. Temperature Effects: Alnico magnets tend to be very stable with respect to temperature. Changes in magnetization are reversible and loss of magnetization can be recovered by remagnetization for temperatures up to 538°C. Applications: Alnico magnets are mainly used for speakers, microphones, motors, measuring instruments, flywheel generators, sensors, holders, stepping...

Angebot anfordern

HME - TECHNOLOGIES GMBH

Schweiz

The material is composed of Iron Oxide, Strontium or Barium, and other materials added. Ferrite magnets are very popular and widely used because of their excellent resistance to demagnetizaion ... The material is composed of Iron Oxide, Strontium or Barium, and other materials added. Ferrite magnets are very popular and widely used because of their excellent resistance to demagnetizaion, corrosion, and their low cost. General Information: Ferrite magnets are manufactured by pressing or sintering. These magnets can be both anisotropic and isotropic. Anisotropic grades are oriented in the manufacturing direction and must be magnetized in the direction of orientation. Isotropic grades are not oriented and can be magnetized in any direction. The basic shape is given by the mold, like segment, disc, ring, rod, bar and block. After pressing the magnet will be sintered, then cut, ground and/or drilled, finally magnetized if desired. The material can withstand corrosion to a great...

Angebot anfordern

HME - TECHNOLOGIES GMBH

Schweiz

This group is formed by the magnets Samarium Cobalt (SmCo5 and Sm2Co17). Their main elements, the so-called Rare Earth Sm and Nd, belong to the lanthanide metal series of the periodic system... This group is formed by the magnets Samarium Cobalt (SmCo5 and Sm2Co17). Their main elements, the so-called Rare Earth Sm and Nd, belong to the lanthanide metal series of the periodic system of elements. General Information: SmCo magnets are manufactured by sintering process. They are anisotropic and can only be magnetized in the direction of orientation. In general, magnetizing fields of approximately 30 to 45KOe are required to saturate SmCo magnets. These magnets possess very high magnetic properties, excellent thermal stability, while remaining resistant to corrosion. These characteristics make SmCo magnets ideal for applications requiring a resistance to wide-ranging temperatures and rough environments. They provide high stability, but cause higher prices as well. Temperature...

Angebot anfordern

HME - TECHNOLOGIES GMBH

Schweiz

Best in magnetic performance and energy. The NdFeB magnet is currently the strongest one available. General Information: Neodymium Iron Boron (NdFeB) magnets, of the Rare Earth class, have been commercially available since the mid -1980's. Their popularity has grown rapidly due to their high Maximum Energy Product and their wide range of available shapes, sizes, and grades. Today, a Remanence of over 1,4 Tesla is possible. Energy products of up to 50MGOe are currently available. The majority of NdFeB magnets are anisotropic and can only be magnetized in the orientation direction. In general, magnetizing fields of approximately 30KOe are required to saturate NdFeB magnets. An important disadvantage of the NdFeB magnet is its sensitivity to corrosion. Therefore, to prevent undesired oxidation, the finnished magnets are coated with a zinc-, nickel-, tin-, al-, au- or epoxy layer. The NdFeB magnets are produced in big blocks which are pressed in a mold and then sintered. A smaller...

Angebot anfordern

HME - TECHNOLOGIES GMBH

Schweiz

Magnets in combination with other products, like holders, locks, speaker systems, magnet modules, accoding to customer design. General Information: HME - Technolgies GmbH offers a full range of magnetic assemblies and has the ability to fabricate multi-component magnetic assemblies to the specification of our customers, such as a complete rotor assembly (metal rotor, magnet segments, seamless steel tube). For further details, please contact HME - Technologies. Temperature Effects: Depending on the magnet material. Applications: Magnets systems are used in a wide array of applications from magnet poles for big (wind-) generators, holders for home, office & factory, point of sales, locks for furnitures. Examples: Holder Magnets, Speaker Systems

Angebot anfordernHersteller/ Fabrikant

Baselstrasse 16

4532 Feldbrunnen - Schweiz

europages empfiehlt Ihnen ebenfalls

Eine Auswahl an Firmen mit ähnlicher Aktivität:

Eine Auswahl an Produkten, die Sie interessieren könnten

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Funktionen: Aus geschliffenem SmCo-Magneten Pulver wird mit Harz gemischt und wie NdFeB-Verbundmagnet geformt Keine Notwendigkeit, beschichtet werden, weil es schwierig ist, zu erodieren und zu oxidieren High-BH (maximal) High-Br und Hc mit Hochbetriebstemperatur, Niedertemperaturkoeffizient, Gegenentmagnetisierung und Zerfallsbeständigkeit Die Hauptprodukte umfassen SmCo5- und Sm2Co17-Magnete, Samarium-Kobaltpulver, verschiedene Baugruppen und mehr OEM-Bestellungen sind willkommen Anwendungen: Weit verbreitet in Motoren, Uhren, Messumformern, Instrumenten, Positionsdetektoren, Generatoren, Radargeräten und mehr

Angebot anfordern

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Funktionen: Mit ausgezeichneter Flexibilität macht es eine besondere Art von Magnet in den Linien der Werbung, Propagandisierung, Druck, Dekoration, Spielzeugherstellung und mehr Kann drinnen und draußen ohne magnetische Kraft verwendet werden Physikalische Eigenschaften: Kann normal unter der Temperatur von -30 bis 55°C arbeiten und kann Temperatur bis zu 65°C in kurzer Zeit standhalten Mit PVC/PSA-Unterlage, Hochtemperaturbeständigkeit Kann in jede Form geschnitten oder mit Löchern als besondere Anforderung gestanzt werden und so wird magnetkautschuk auch flexible Gummi genannt Kann matt oder glänzend sein Maßgeschneiderte Farben werden akzeptiert Kann mit Klebeband auf einer Seite aufgetragen werden Normaler Dickenbereich: 0,3 bis 3 mm Anwendungen: Verwendet für Linie von Spielzeugherstellung, stationär, Druck, Werbung, Propaganda und Dekoration OEM/ODM-Aufträge sind willkommen Beste Dienstleistungen mit professionellem Personal

Angebot anfordern

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Alnico Magnet ist ein Gussmagnet, bestehend aus Aluminium, Nickel und Kobalt. Obwohl es leicht entmagnetisiert werden kann, ist es sehr hitzebeständig (sein Curie-Punkt ist 850°C) und ist nicht leicht gebrochen, also mechanisch stark. Es ist traditionell beliebt für verschiedene Meter und Telekommunikations-Tools, und vor kurzem wird es für Watt-Stunden-Meter sowie Anti-Kriminalität-Geräte verwendet. In der Regel auf kleinere Größen beschränkt Formen: Ring, Block, Scheibe, Zylinder, Lichtbogen, Segment und mehr Sie haben ein hochrestliches Induktions- und Energieprodukt und eine geringe Zwangskraft und die häufigste Qualität ist 5 und 8 Hohe Qualität, wettbewerbsfähiger Preis, bester Service

Angebot anfordern

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

High-Performance-Kostenverhältnis Leicht in verschiedene Größen geformt Material: NdFeB, Neodym, Seltenerdmagnet Beschichtung: Ni, Zn, Ni-Cu-Ni, gold- oder epoxybeschichtet Typen: N35-N52, 35M-50M, 30H-48H, 30SH-45SH, 30UH-40UH und 28EH-38EH Ringtyp: Die Lochgröße kann einschließlich des Senklochmagneten für die Senkschraube bestimmt werden Technologie: Anwendung neuer sinterer NdFeB-Magnettechniken und -geräte wie Guss, HDDR-Technologie Anwendungen: weit verbreitet in vielen Bereichen wie Audio-Instrumente, Messgeräte, Motoren, Luftfahrt, Elektronik, Instrumente, medizinische Instrumente und dergleichen, besonders geeignet für die Entwicklung von Hochleistungs-, Kompakt- und Leichtprodukte Hohe Qualität, wettbewerbsfähiger Preis, bester Service

Angebot anfordernMehrere Angebote erhalten

Mit nur einer Anfrage erhalten Sie mehrere Angebote von geprüften Anbietern

- Nur relevante Anbieter

- Datenschutzkonform

- 100% kostenlos